RESEARCH

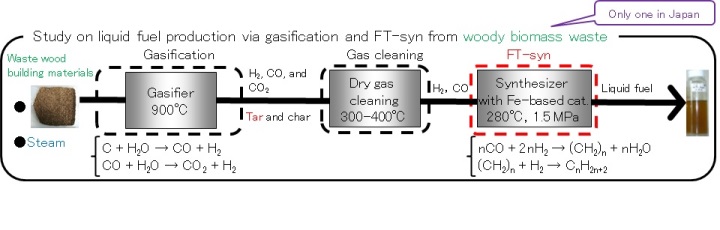

Study on liquid fuel production process from woody biomass waste (Biomass to Liquid, BTL)

Gasification of waste wood building materials

There are five million tons of waste wood building materials in a time

span of a year in Japan. 50% of the energy used in a waste wood building

materials recycling plant is light oil used as the fuel for a heavy machine.

The production of this light oil from waste wood building materials promises

not only the recycling promotion but also the reduction of CO2 emissions.

However, wood building materials used from 1960's through until 2000's

are treated with preservatives or pesticides using CCA (copper chromated

arsenate). The investigation of the phase and substance behavior of arsenic

in the gasification of waste wood building materials is required because

arsenic may cause adverse effects on a living organism, gasifier, and FT

(FischerTropsch) catalyst.

In the study, an optimum gasification condition for the H2/CO molar ratio

of 2 in the gasified gas of waste wood building materials and the phase

and substance behavior of arsenic (As) in the gasification for the purpose

of liquid fuel production were investigated through the use of a fixed-bed

reactor under the conditions of the H2O/C molar ratios of 0.5-2.6 in the

feed and the temperatures of 600-800 ºC.

Dry gasification gas cleaning using waste wood building materials char

The fuel gas from gasification processes contains various amounts of impurities

and particulate originating from the solid fuel and attrition products

from the bed material. Hot gas cleaning also implies chemical manipulations

of the product gas to meet environmental as well as technical standards.

High molecular weight products, tars, and other components like alkali

trace elements may cause in the condensed phase severe operational problems.

These have to be removed before the gas product can qualify as fuel for

gas engine or gas turbine purposes.

From these backgrounds the research plan is development of Hot Gas Cleaning

from wood waste building (Biomass) Gasification, various method for tar

removal have been investigated in the different range of gas cleaning temperatures.

At low temperatures, <403K, the tar was removed by cooling with water

or adsorption on adsorbent. At high temperatures, 873 to 1173 K, it was

cracked by catalysts such as Ni/Al2O3 and dolomite .

Activated carbons as an adsorbent are extensively used to remove pollutants

from exhaust gases at low temperatures . Some researchers removed organic

pollutants such as polycyclic aromatic hydrocarbons (PAH) generated from

combustion process by the adsorption to activated carbon at 423K. On the

contrary, the method for tar removal at medium temperature ranging from

473 to 773 K has several advantages compared with other methods (Hamelinck

et al, 2002). Compared with the tar removal methods at a low temperature,

this method has the following advantages: (1) the drain could be treated

more easily, and (2) in the synthesis of liquid fuels using producer gas

from biomass gasification, the method can supply the gas to the liquid

fuel synthesis process without cooling below the required temperature (473-573K).

However, the tar removal at medium temperatures of 473 to 773K was hardly

reported using carbonaceous materials. In the research plan, the hot gas

cleaning of producer gas generated from waste woods, such as waste wood

building material, gasification will be investigated using char produced

in their gasification. Various carbonaceous materials as a bed additive

will be used to compare the ability of tar removal at the medium temperature.

Fischer-Tropsch synthesis for liquid fuel production from waste wood building materials

Light oil for diesel fuel mainly consists of n-paraffin. In FTS, olefin

is relatively much produced with an Fe-based catalyst, whereas paraffin

is relatively much produced with a cobalt (Co) -based catalyst. Thus, a

Co-based catalyst has an advantage for the production of light oil by FTS

from a viewpoint of desired products. However, the cost of an Fe-based

catalyst is generally lower than that of a Co-based catalyst. This allows

an Fe-based catalyst to produce paraffin by the hydrogenated reaction in

another reactor after olefin production by FTS.

In the present study, the FTS of syngas using an Fe-based catalyst is experimentally examined in terms of the primary light oil yield and carbon mass balance in order to produce HCs such as diesel fuel. The effect of the chemical species, such as potassium as a promoter, included in the Fe-based catalyst on the FTS is investigated.

Environmental and economic analysis of liquid fuel production process from woody biomass waste

Recently, some researchers have conducted experimental studies on the synthesis

of liquid fuels via woody biomass gasification. In addition to technical

research and development, the environmental and economic analysis of this

process is required for commercialization. In this study, gasification

by external heating (i.e., only with steam) is adopted and focused on heat

and power resources. From an economic viewpoint, the use of inexpensive

heat and power resources results in a low production

cost, while the supply of external heat and power by fossil resources does

not lead to CO2 reduction. In the present study, the process is designed.

The light oil yield and energy recovery rate in the processes and the amount

of input energy for the processes are investigated. In addition, the environmental

and economic analysis of the processes is performed from the viewpoint

of CO2 emission and capital and operating costs.

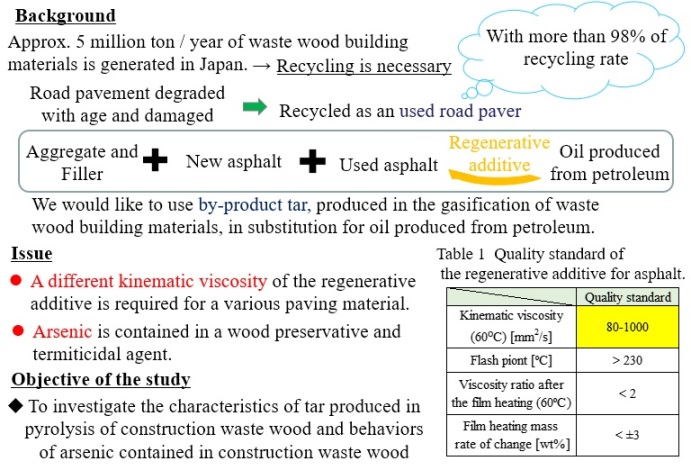

Study on application development of waste wood building materials tar to recycled asphalt

emission and capital and operating costs.

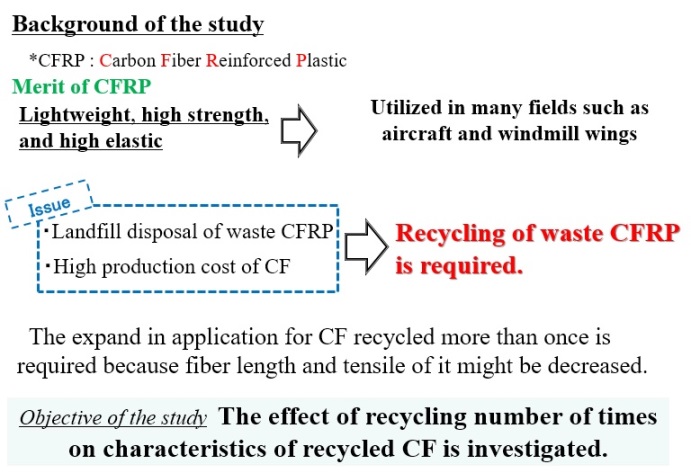

Study on application development of recycled CFRP waste