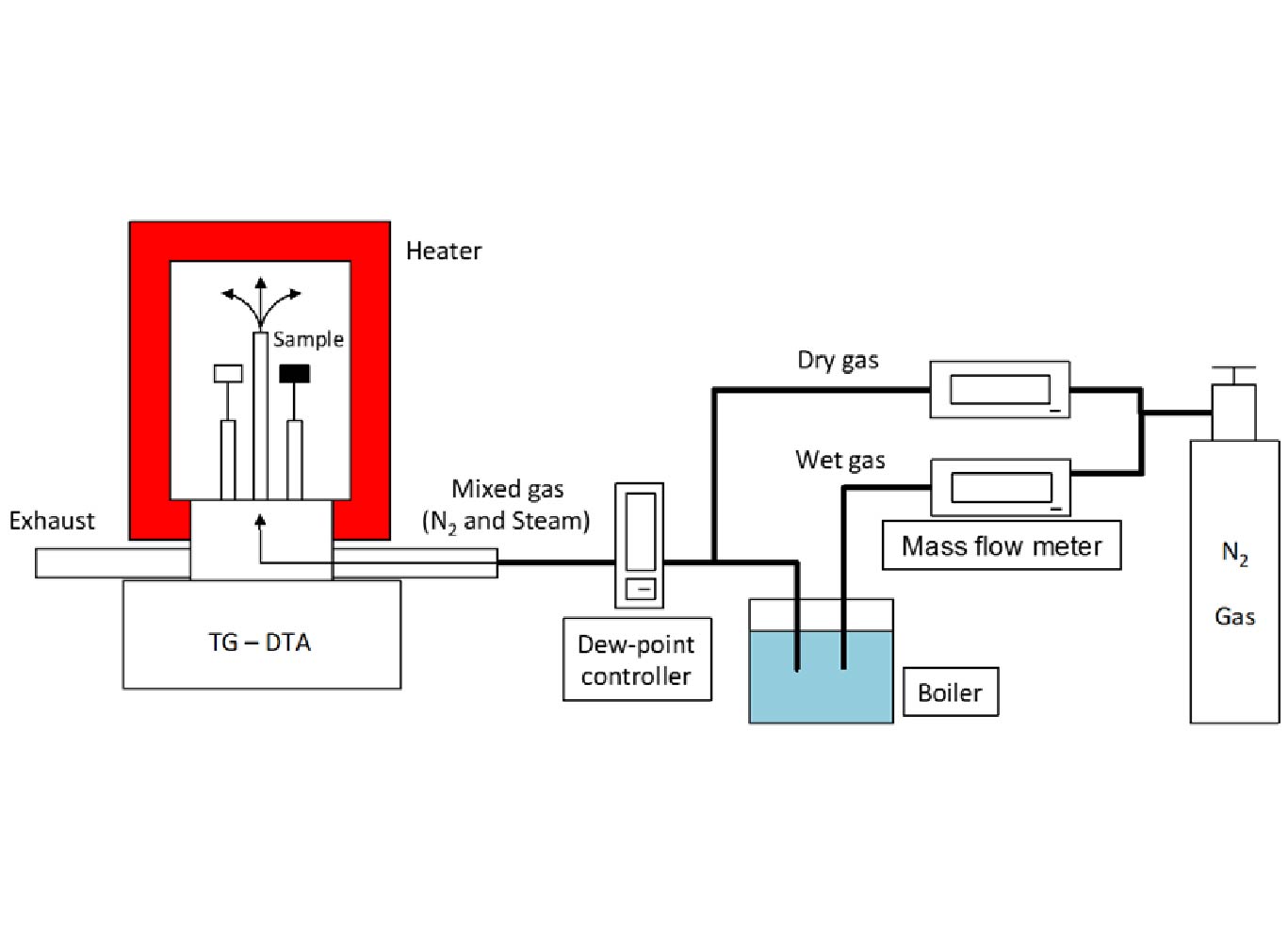

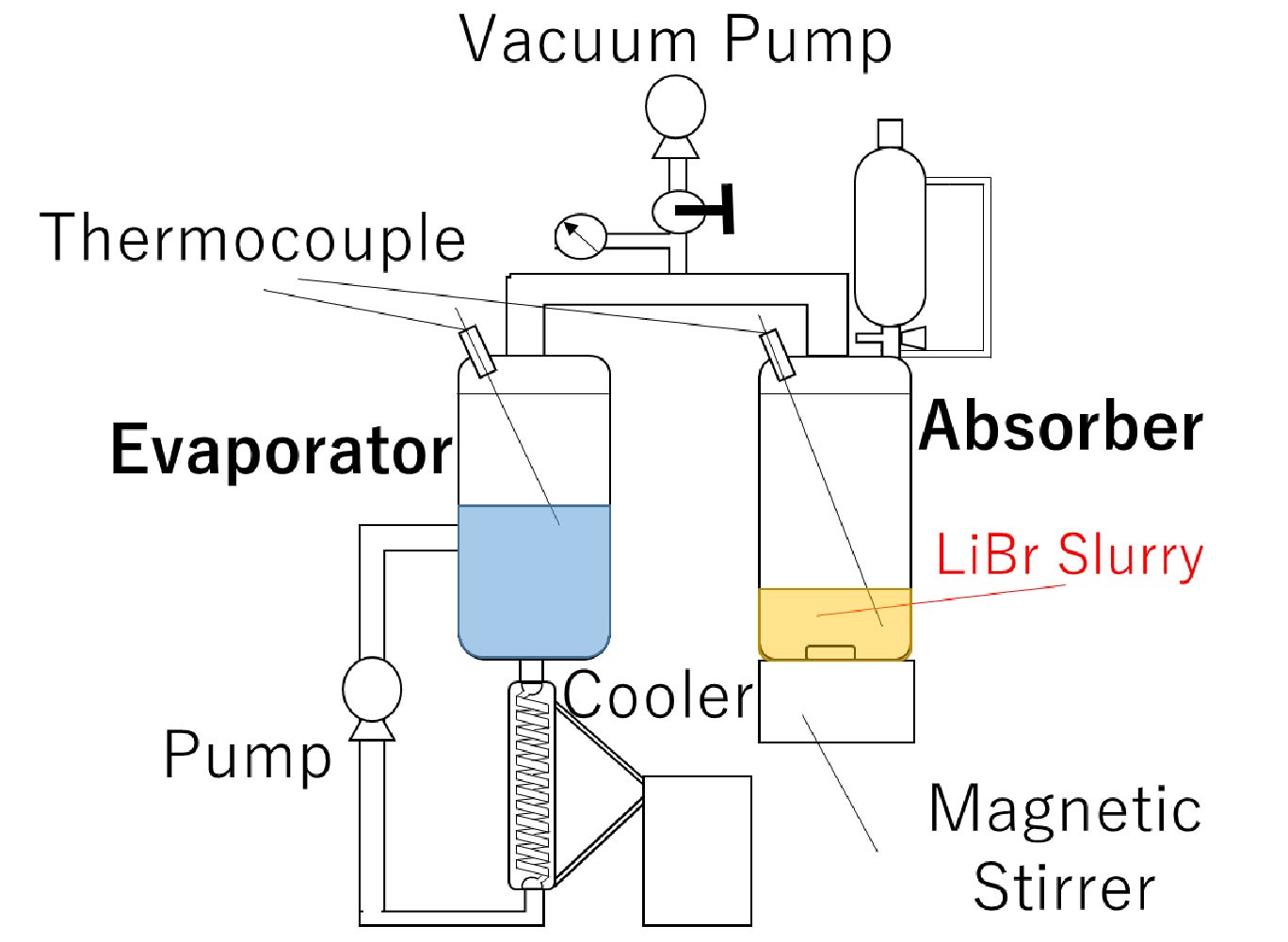

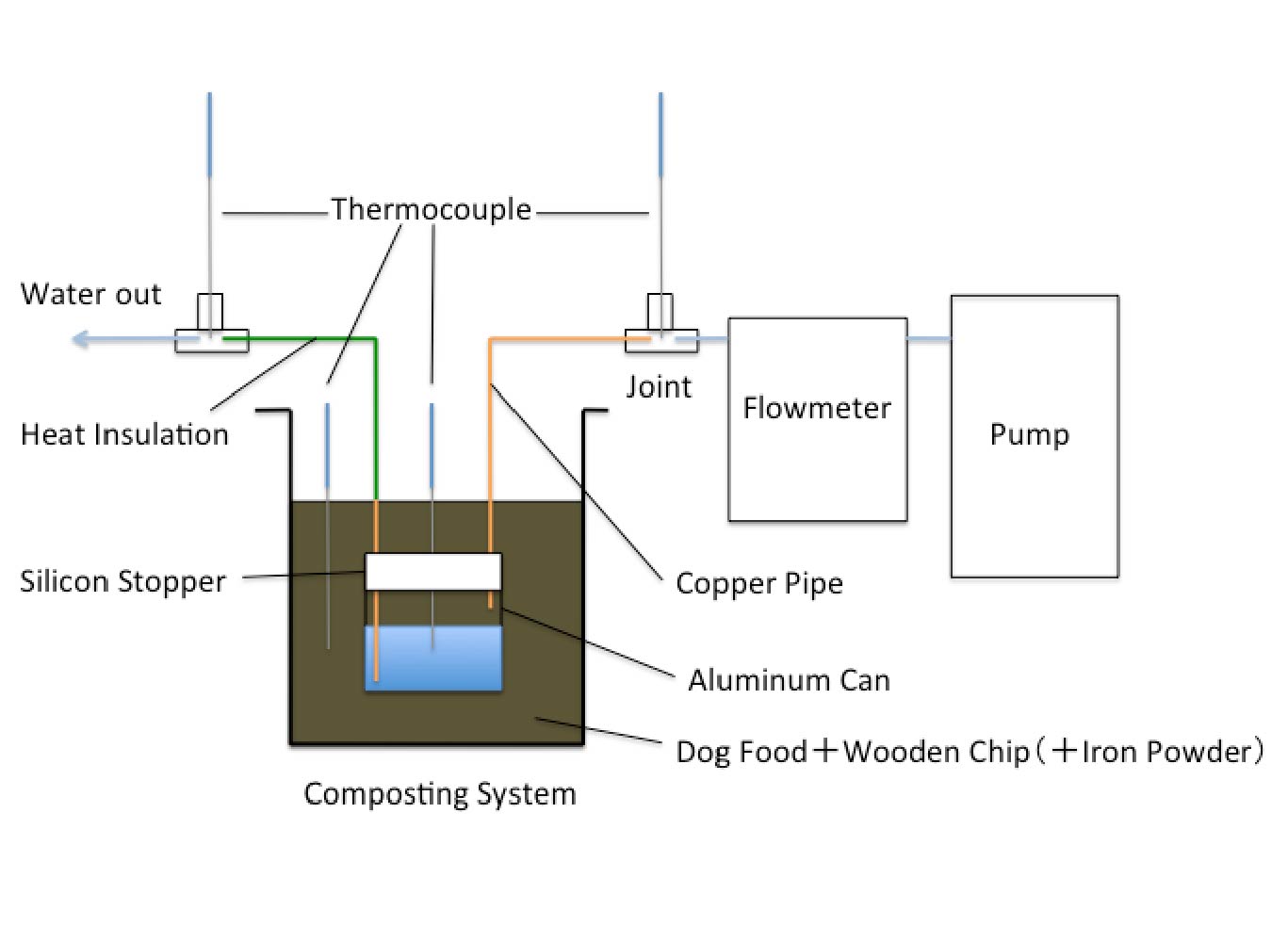

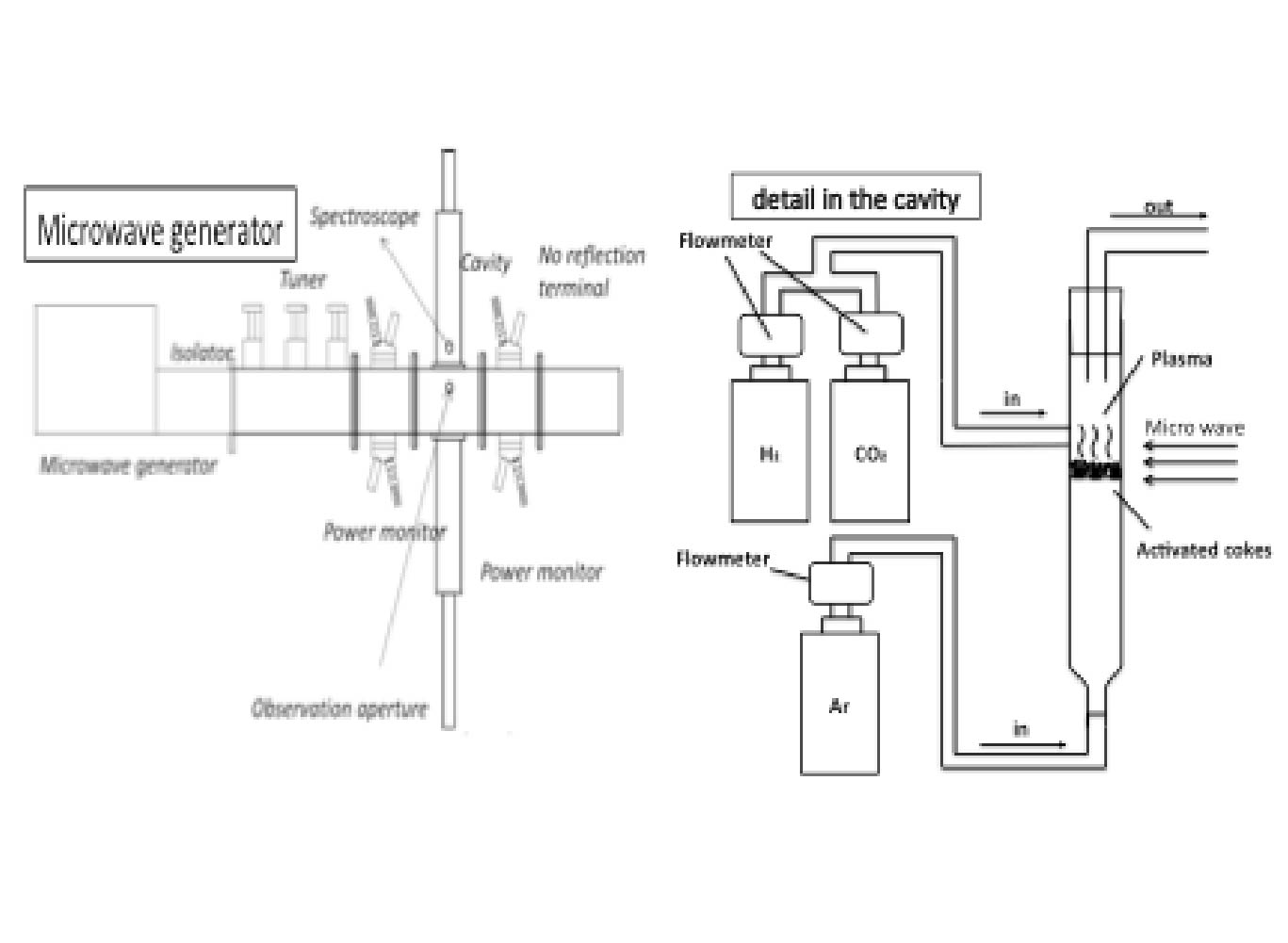

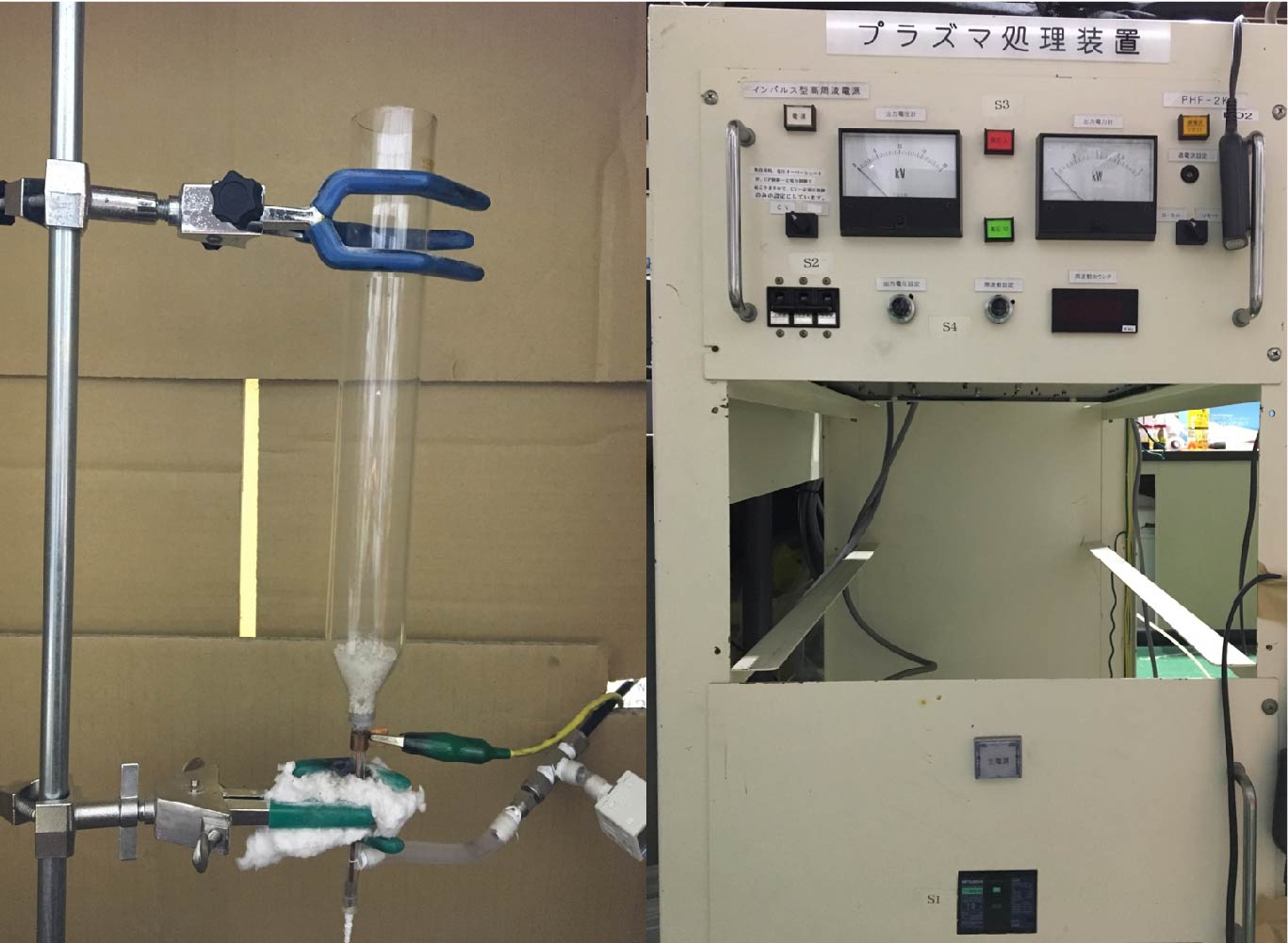

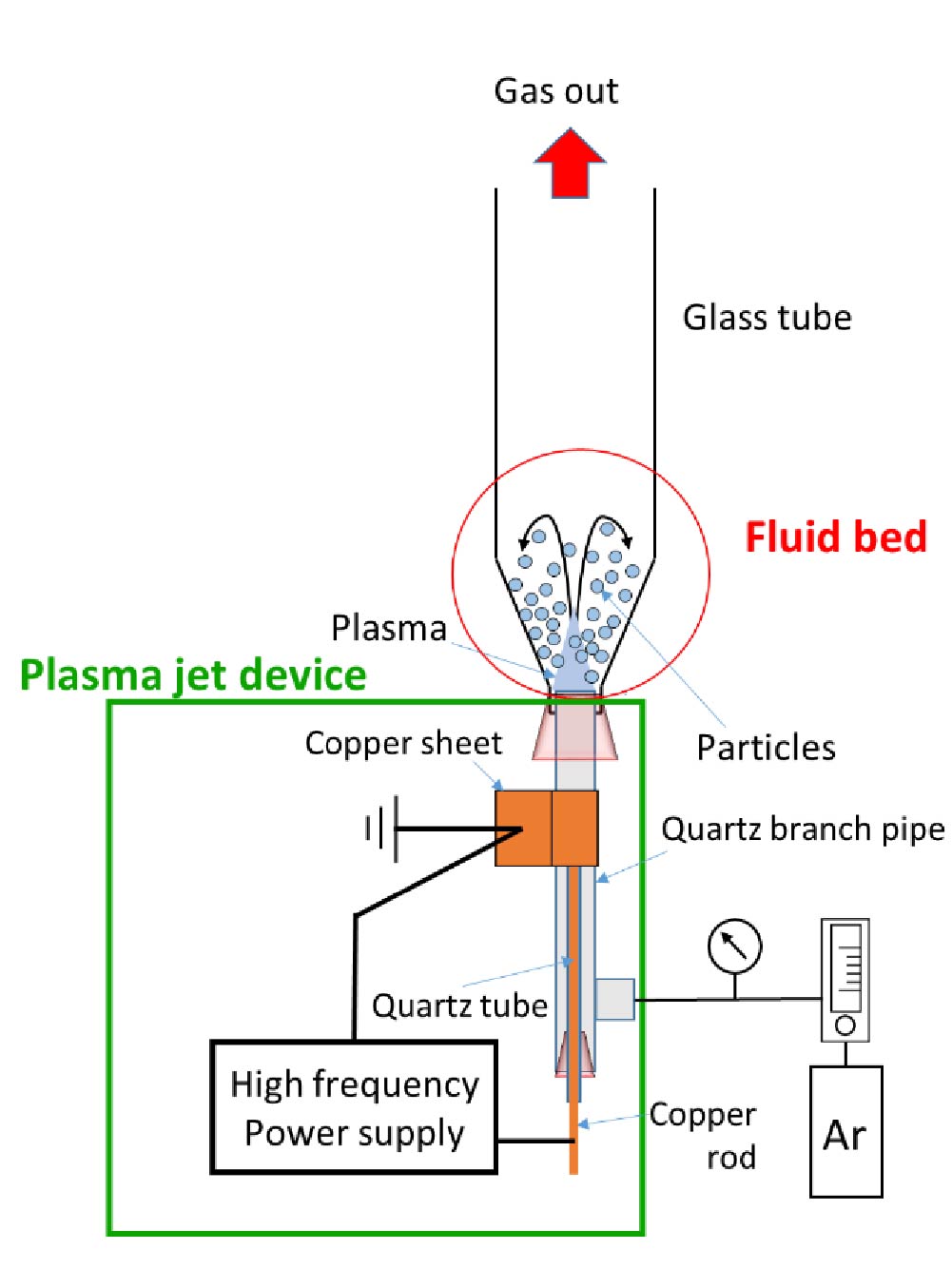

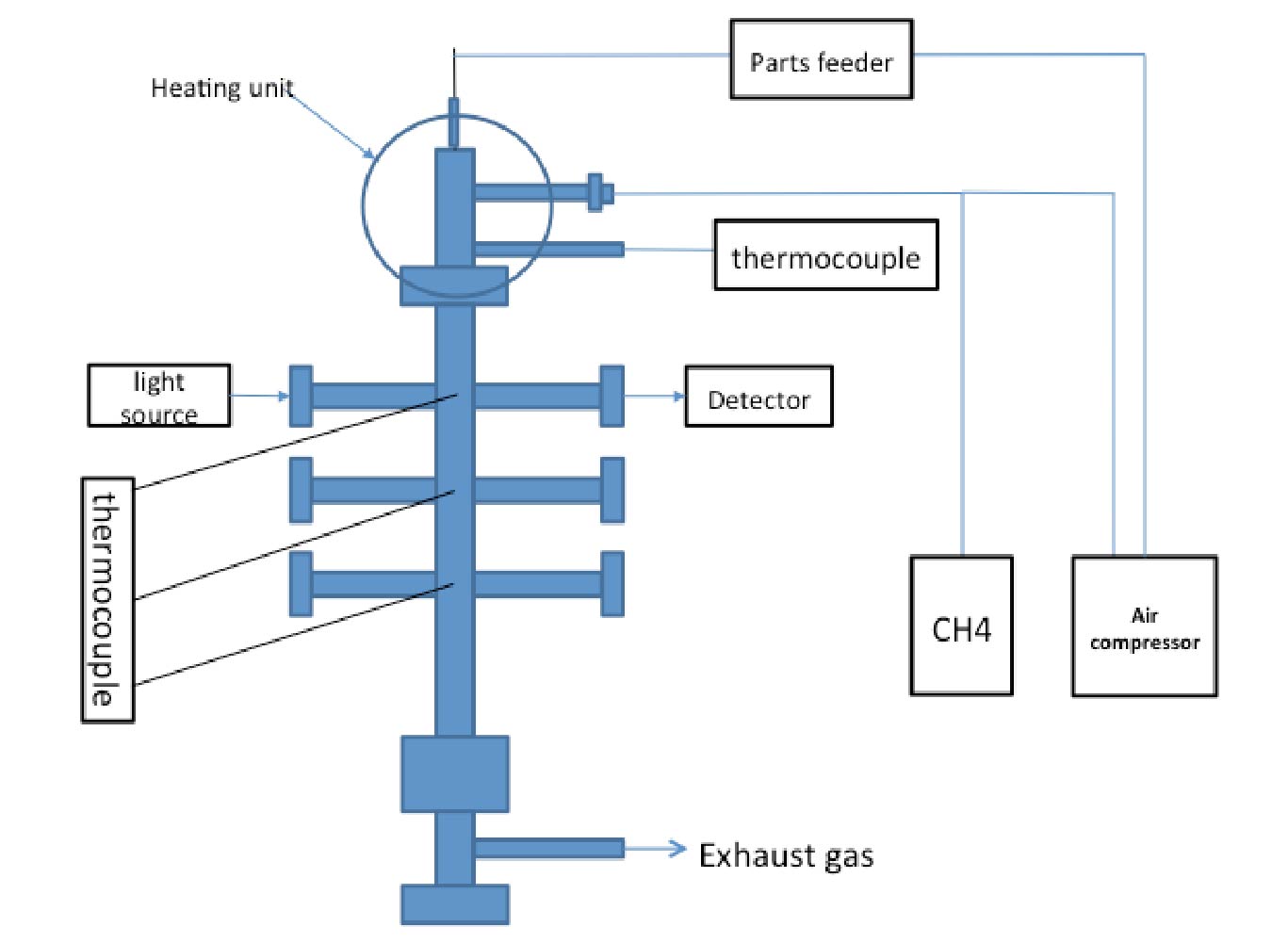

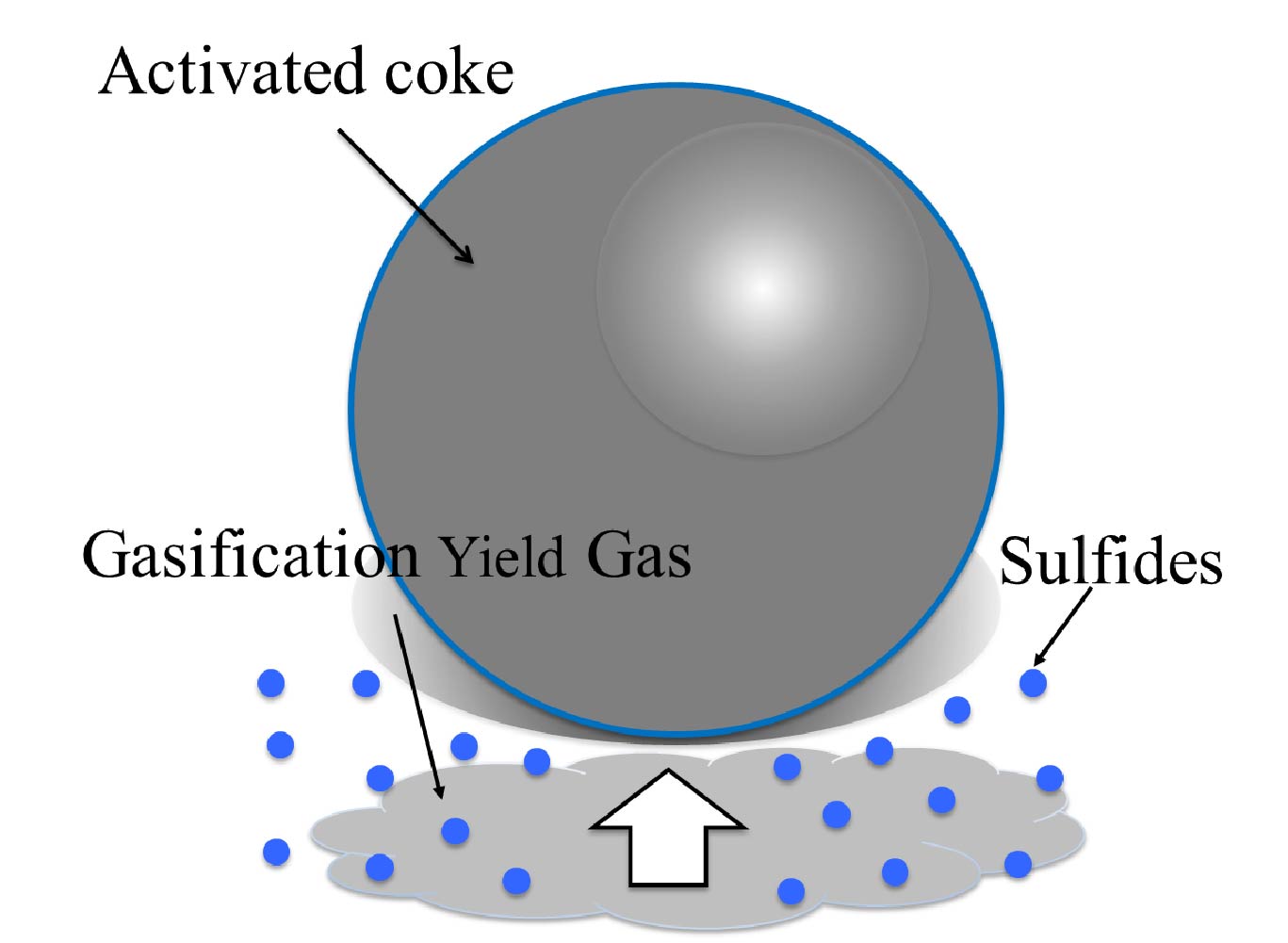

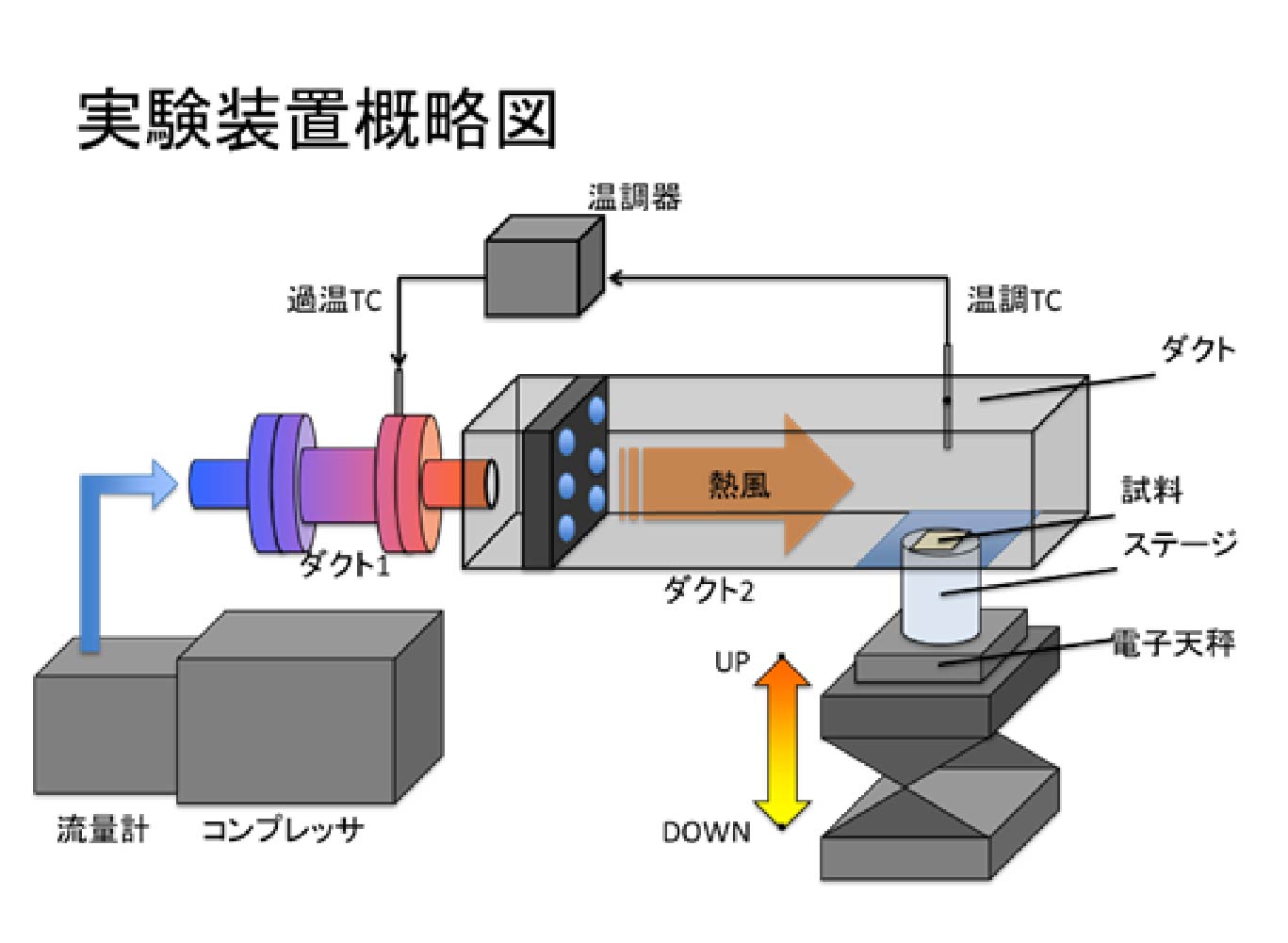

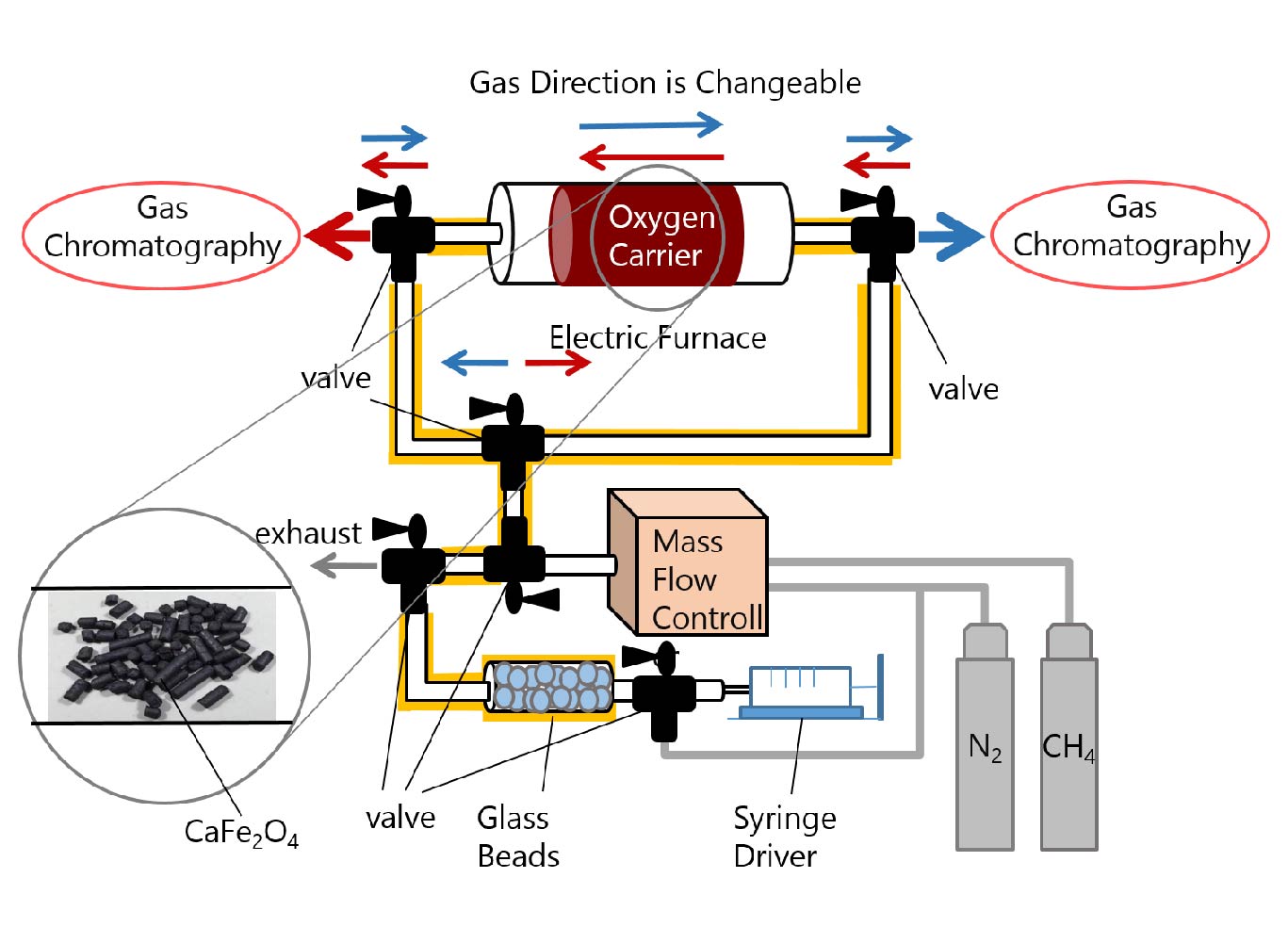

I am studying hydrogen production. In order to realize hydrogen society, reduction of hydrogen production cost is a challenge today. So we focused attention on the chemical looping process. Calcium ferrite is immobilized in a reactor and hydrogen production by oxidation reduction by gas makes it possible to achieve high efficiency. In this research, we manufacture gas switching hydrogen production equipment, when reducing calcium ferrite, methane gas flows in, and when calcium ferrite is oxidized, water vapor is flowed in. I’m evaluating hydrogen production amount.