Recently, thin-film solar cells have attracted wide interests owing to rapid expansion for solar cell production. Nevertheless, the size of thin-film solar cell modules (panels) is generally as large as 1m, and there exists structural inhomogeneity on the module. Accordingly, in order to improve efficiency and productivity of solar cell modules, the development of large-area structural characterization method is quite important. In the research center, Solar Cell Module Characterization R&D Group has been newly created particularly to establish structural characterization method for various solar cell modules.

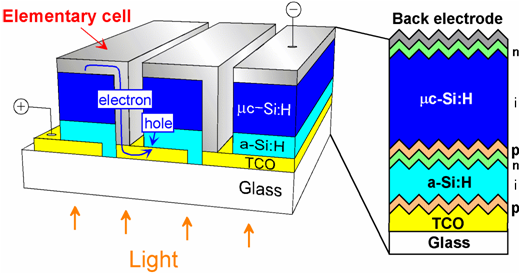

In order to lower the production cost of thin-film solar cell modules, the development of high efficiency modules becomes increasing important. For silicon thin-film solar cells, consisting of hydrogenated amorphous silicon (a-Si:H) and microcrystalline silicon (?c-Si:H), large-area modules can be fabricated using plasma processing. In a-Si:H/?c-Si:H tandem modules (Figure 1), however, the module structure is rather complicated, and elementary cells in the module are connected electrically in series. As a result, the photocurrent in the whole module is determined by an elementary cell that shows the lowest current. In actual modules, the number of elementary cells is around 80 and, if there is structural inhomogeneity on the module, the output power of the module reduces. Accordingly, to increase the output power of module and thus to reduce the production cost, the development of structural characterization method is quite essential. Based on results obtained from such characterization, the large-area processing should then be improved.

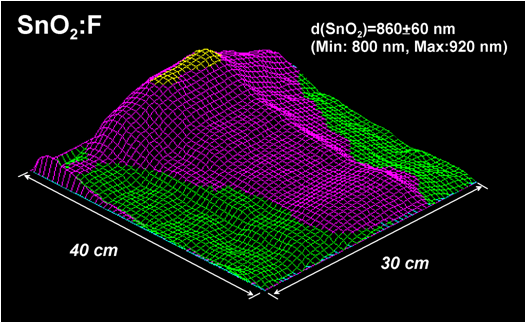

In this R&D Group, the non-destructive and high-precision structural characterization method for large-area solar cells has been developed using optical measurement technique called spectroscopic ellipsometry. Furthermore, since 2009, this group has been collaborating with Dainippon Screen MFG that developed a spectroscopic ellipsometry instrument for large-area solar cell module characterization (Figure 2). Figure 3 shows an example of large-area characterization using this instrument (RE-8000). In this case, the thickness of a SnO2:F transparent conductive oxide film fabricated on a glass substrate (30x40 cm2) has been characterized. From Fig. 3, it can been seen that the variation of the SnO2:F film thickness is larger than 100 nm. In particular, when the thickness of SnO2:F layers increases, the light transmission in the infrared region reduces, which in turn decreases the photocurrent in the ?c-Si:H layer. Therefore, the structural characterization by spectroscopic ellipsometry is quite important for achieving high module efficiency.

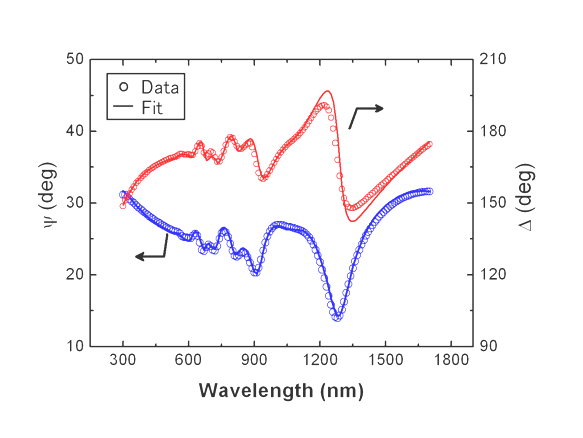

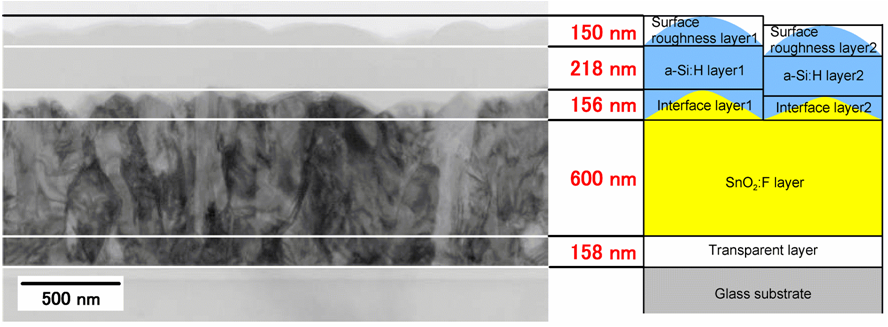

At this stage, to perform structural characterization of silicon thin-film tandem module, this group has been developing characterization methods for textured solar cell structures and optical database for silicon thin-film component layers. Figure 4 shows a characterization example for the textured a-Si:H/SnO2:F structure, developed recently. In this characterization, the sample is an a-Si:H i layer formed on a SnO2:F layer having a textured structure. In general, for silicon thin-film solar cells, textured SnO2:F layers are applied to enhance light absorption in silicon layers. However, a-Si:H layers deposited on the textured substrate show structural inhomogeneity and the conventional analysis is difficult to use. Accordingly, for the analysis of this textured structure, newly developed analysis method has been applied to perform high-precision ellipsometry analysis. Figure 4 shows measured and calculated ellipsometry spectra obtained from the a-Si:H/SnO2:F structure. In particular, the solid lines in Fig. 4, calculated from the developed analytical model, show quite good agreement with the measured data. Furthermore, the thicknesses of each layers obtained from this ellipsometry analysis agree quite well with the layer thicknesses measured from TEM (Figure 5). The above results indicate that new analytical method developed is quite effective and ellipsometry characterization of complicated textured structures can be performed. From such researches, this group has been trying to establish structural characterization techniques for various solar cells and to contribute to the R&D in solar cell industry.

Figure 1.丂Module structure of silicon thin-film tandem solar cells

Figure 2. Large-area spectroscopic ellipsometry characterization instrument (Dainippon Screen MFG: RE-8000)

Figure 3. Thickness variation in a textured SnO2:F layer characterized by RE-8000