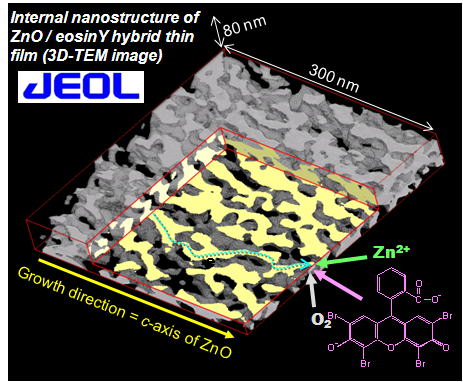

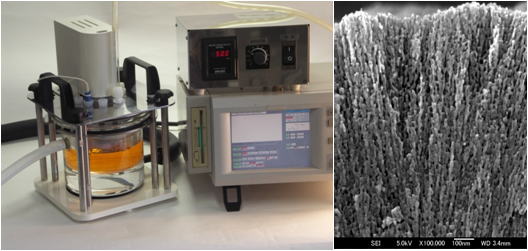

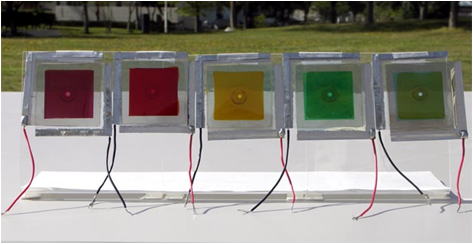

Our group is engaged in the R&D or dye-sensitized solar cells (DSSCs) based on the originally developed electrodeposition of nanostructured ZnO thin films. DSSCs are attracting world-wide attention as the most promising candidate of cost effective next-generation PV systems. In the traditional method for fabrication of photoelectrodes, high temperature sintering of metal oxide nanoparticles was inevitable, so that optically transparent substrate was limited to heat resistant glass. With our electrodeposition method, neither high temperature nor aggressive chemicals are needed, so that use of low cost and light weight plastic substrates. The electrodeposited "porous crystalline" zinc oxide (ZnO) has high surface area needed for adsorption of high amount of dye molecules to harvest the sun light as well as high crystallinity needed for efficient transport of electron. Since colorful organic dyes are combined with ZnO, solar cells can also be furnished in various colors. From these technological features, development of low cost, light weight, flexible, colorful and see-through plastic solar cells has become possible.

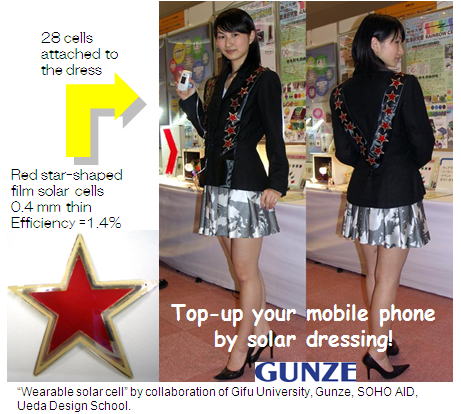

Despite of their high efficiencies, traditional crystalline silicon solar cells are known to be too expensive to wide-spread. However, challenges for new types of solar cells are not only the improvement of the efficiency/cost balance. As we aim installation of PV systems in much higher area than today's level, we need to seek for chances to install them on the roof top of large buildings such as factory buildings whose roof construction is not as rigid as that of the private houses. Noise insulating walls of highway can also be converted to PV panels for which use of brittle glass panels are impossible. Reducing weight plastic PV systems therefore extend chances for wide area applications. What we aim is "ubiquitous" power generation by PV systems installed everywhere in our living surroundings. Also, lightness, flexibility and colorfulness open possibilities for mobile power applications such as mobile phones.

Our research stems for all aspects of DSSCs, including development of new materials for inorganic semiconductors, organic dyes and electrolytes for high efficiency and long life, device fabrication technologies for cost reduction and reliability, and photoelectrochemical measurements for precise analysis for device functions. Members of the group are specialists of these studies. Each research topic is linked to companies working for industrialization of DSSCs. Intimate collaboration with industrial partners also helps students to develop mind and skills to contribute to the future development of PV industries.

"The true innovation begins when new technology (hardware) meets ideas (software) to draw benefits from the new technology." We have launched "Universal Solar Cell (UNISOL) Consortium" to promote mixing and exchanges of technology, material and people not only between the university and companies, but also among the companies. The commitment of the DSSC R&D group of CIPS is not just about the technologies for high efficiency and stability but also applications of these new devices to open up new industrial field.

Originally developed electrodeposition system using RDE principle and “porous crystalline” nanostructured ZnO thin film.

Flexible, colorful and see-through solar cells.